How Many Types of Industrial Safety Are There?

Industrial safety is a multifaceted discipline designed to protect workers, equipment, and the environment from harm. With the ever-evolving nature of industrial operations, the field of industrial safety encompasses a broad range of strategies and practices. In this blog post, we will explore the different types of industrial safety, offering a comprehensive overview of how these various approaches work together to create a safer work environment.

1. Occupational Safety

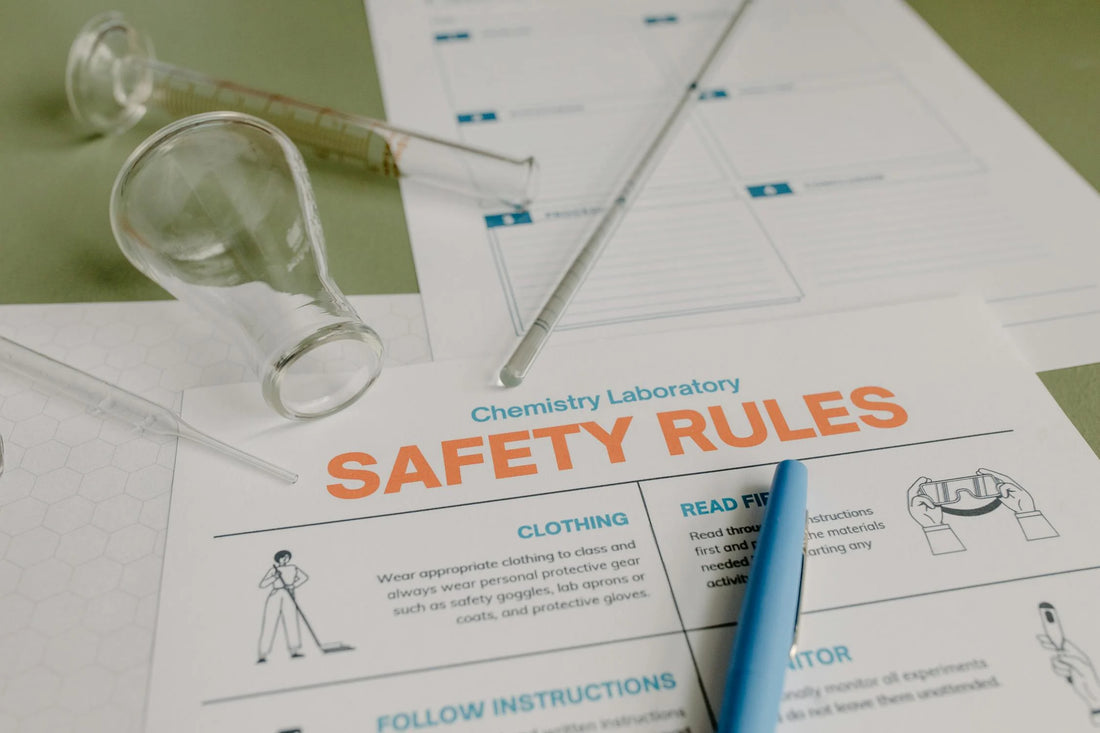

Occupational safety focuses on preventing injuries and illnesses that result from workplace conditions. This includes physical hazards like machinery, chemicals, and ergonomic issues. Key practices in occupational safety include:

- Personal Protective Equipment (PPE): Using safety gear such as helmets, gloves, and goggles to protect workers from specific hazards.

- Safety Training: Educating employees about safe work practices, emergency procedures, and the proper use of PPE.

- Hazard Assessment: Regularly inspecting the workplace for potential dangers and addressing them proactively.

Occupational safety is foundational because it deals directly with preventing harm to individuals in their day-to-day tasks.

2. Process Safety

Process safety is crucial in industries where hazardous processes or materials are used, such as chemical manufacturing or oil refining. The goal is to prevent catastrophic events like explosions or toxic releases. Key elements include:

- Hazard Analysis: Evaluating processes to identify potential risks and implement safeguards.

- Safety Instrumented Systems (SIS): Using automated systems to monitor and control critical process parameters.

- Incident Investigation: Analyzing accidents or near-misses to improve safety measures and prevent recurrence.

Process safety is essential for industries dealing with high-risk processes, aiming to prevent large-scale incidents that could have severe consequences.

3. Environmental Safety

Environmental safety involves protecting the natural environment from the adverse effects of industrial activities. This includes preventing pollution and managing waste. Key practices include:

- Waste Management: Implementing strategies for proper disposal, recycling, and reduction of industrial waste.

- Pollution Control: Using technologies and practices to minimize emissions and discharges into air, water, and soil.

- Compliance with Regulations: Adhering to environmental laws and standards to mitigate the impact of industrial operations on the environment.

Environmental safety is vital for ensuring that industrial activities do not harm ecosystems or public health.

4. Fire Safety

Fire safety is a specialized area of industrial safety focused on preventing and responding to fires. Key aspects include:

- Fire Prevention: Implementing measures to reduce the likelihood of fire, such as proper storage of flammable materials and regular maintenance of electrical systems.

- Fire Detection: Installing and maintaining smoke detectors, fire alarms, and sprinkler systems to detect and suppress fires early.

- Emergency Response: Training employees on fire evacuation procedures, conducting regular fire drills, and ensuring access to firefighting equipment.

Fire safety is critical because fires can cause significant damage to facilities, equipment, and lives.

5. Electrical Safety

Electrical safety is concerned with preventing accidents related to electrical systems. This includes:

- Safe Electrical Installations: Ensuring that electrical systems are installed correctly and maintained according to safety standards.

- Training and Procedures: Educating employees on the risks associated with electrical work and safe practices.

- Regular Inspections: Conducting routine checks of electrical equipment and wiring to identify and address potential hazards.

Electrical safety is crucial for avoiding electrical shocks, fires, and equipment damage.

6. Ergonomic Safety

Ergonomic safety focuses on designing workspaces and tasks to fit the physical capabilities of workers, reducing strain and preventing musculoskeletal injuries. Key considerations include:

- Workstation Design: Creating workspaces that allow for natural body postures and movements.

- Task Design: Adjusting tasks to minimize repetitive movements and heavy lifting.

- Training and Ergonomic Tools: Educating workers on proper techniques and providing tools that reduce physical strain.

Ergonomic safety is important for reducing the risk of injuries related to repetitive strain and poor posture.

7. Health and Wellness Safety

Health and wellness safety encompasses broader aspects of worker well-being beyond immediate physical safety. This includes:

- Occupational Health Programs: Implementing programs to monitor and improve workers' overall health, including regular health screenings and vaccination programs.

- Mental Health Support: Providing resources and support for mental health, including stress management programs and access to counseling services.

- Work-Life Balance: Promoting practices that support a healthy work-life balance, which can improve overall job satisfaction and reduce burnout.

Health and wellness safety is essential for maintaining a holistic approach to worker well-being.

8. Transportation Safety

In industries where transportation of goods and materials is a key activity, transportation safety becomes crucial. Key practices include:

- Vehicle Maintenance: Regularly servicing and inspecting transportation vehicles to ensure they are safe to operate.

- Driver Training: Providing training for drivers on safe driving practices and regulatory compliance.

- Loading and Unloading Procedures: Implementing safe practices for loading and unloading materials to prevent accidents and injuries.

Transportation safety is important for preventing accidents and ensuring the safe delivery of goods.

9. Construction Safety

Construction safety focuses on the unique hazards associated with construction sites. Key aspects include:

- Site Safety Plans: Developing and implementing safety plans tailored to the specific risks of a construction site.

- Fall Protection: Using safety harnesses, guardrails, and other fall prevention measures.

- Tool and Equipment Safety: Ensuring that construction tools and equipment are well-maintained and used correctly.

Construction safety is vital due to the high-risk nature of construction work and the potential for serious injuries.

10. Safety Culture

Creating a strong safety culture involves fostering an environment where safety is a shared responsibility and priority among all employees. Key elements include:

- Leadership Commitment: Ensuring that leaders actively support and promote safety initiatives.

- Employee Involvement: Encouraging workers to participate in safety programs and report hazards.

- Continuous Improvement: Regularly reviewing and updating safety practices based on feedback and incident analysis.

Safety culture is crucial for embedding safety into the organizational ethos and ensuring sustained compliance with safety practices.

You Can Trust Nova Industrial Safety

Industrial safety encompasses a wide range of practices and strategies designed to protect workers, equipment, and the environment. From occupational and process safety to ergonomic and environmental concerns, each type of safety addresses specific aspects of risk management in the industrial setting. By integrating these diverse safety approaches, organizations can create a comprehensive safety program that minimizes risks and promotes a culture of safety.

Understanding and implementing these various types of industrial safety helps ensure a safer, more productive workplace. As industries continue to evolve, the principles of industrial safety will remain fundamental to protecting people and processes, ultimately contributing to a more secure and efficient industrial environment.

Sources: