-

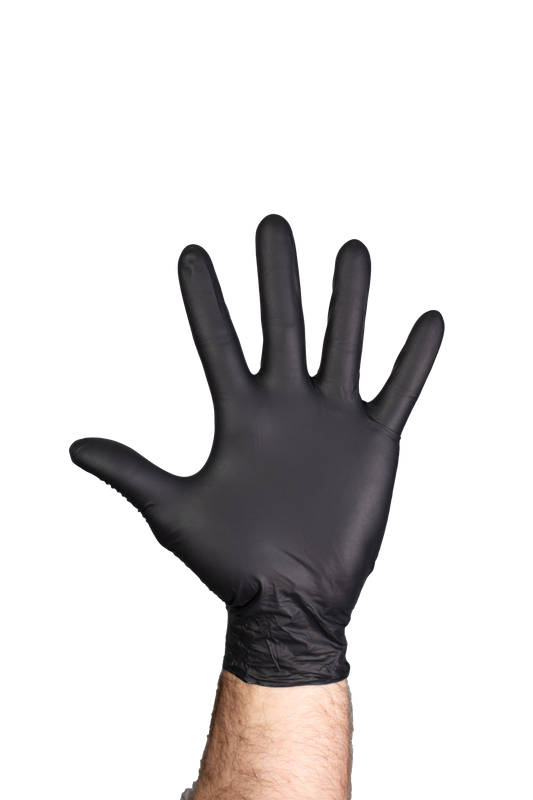

4 MIL POWDER FREE BLUE NITRILE GLOVES - 10 Boxes of 100

Regular price $80.00 USDRegular priceUnit price per -

6 MIL POWDER FREE NITRILE GLOVES - 10 Boxes of 100

Regular price $110.00 USDRegular priceUnit price per$139.98 USDSale price $110.00 USDSale -

BIG WIPES™ HAND WIPES - 80 Wipes per Tub

Regular price From $100.00 USDRegular priceUnit price per -

-

PRO LINE ABC FIRE EXTINGUISHER W/ WALL HANGER

Regular price From $69.90 USDRegular priceUnit price per -

2D ECONOMY FLASHLIGHT W/BATTERIES - Pack of 2

Regular price $5.99 USDRegular priceUnit price per -

SPRAY NINE™ DISINFECTANT SPRAY 32oz - Box of 12

Regular price $90.00 USDRegular priceUnit price per -

-

12/3 EXTENSION CORDS WITH LIGHTED END

Regular price From $99.99 USDRegular priceUnit price per -

ELECTRICAL TAPE - Pack of 10

Regular price $29.90 USDRegular priceUnit price per$2.17 USDSale price $29.90 USD -

CHIP BRUSHES - Pack

Regular price From $28.00 USDRegular priceUnit price per$9.29 USDSale price From $28.00 USD -

-

5 GALLON SAFETY CAN

Regular price $166.99 USDRegular priceUnit price per$47.62 USDSale price $166.99 USD -

80oz PINE-SOL - Pack of 3

Regular price $89.70 USDRegular priceUnit price per -

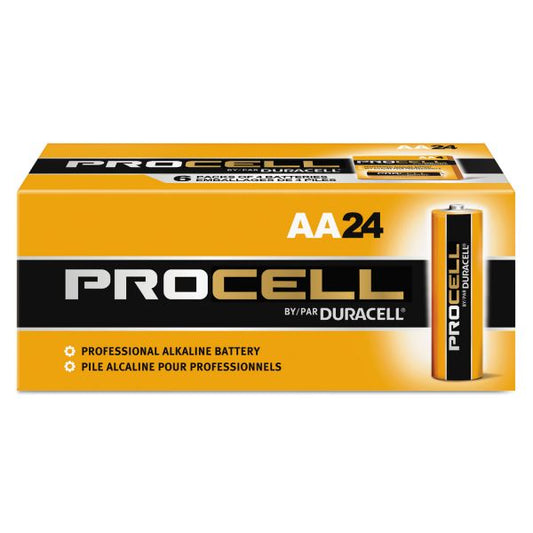

DURACELL PROCELL BATTERIES

Regular price From $23.90 USDRegular priceUnit price per -

X80 WHITE WYPALL RAGS - 1 Box

Regular price $39.90 USDRegular priceUnit price per -

-

WATER-BASED INVERTED MARKING PAINT - Box of 12

Regular price $96.00 USDRegular priceUnit price per -

CLOROX DISINFECTING WIPES - Box of 12

Regular price $120.00 USDRegular priceUnit price per -

SCRUBS IN A BUCKET - Pack of 6

Regular price $120.00 USDRegular priceUnit price per -

55 GALLON TRASH CAN LINER

Regular price $54.90 USDRegular priceUnit price per$29.91 USDSale price $54.90 USD -

Sale

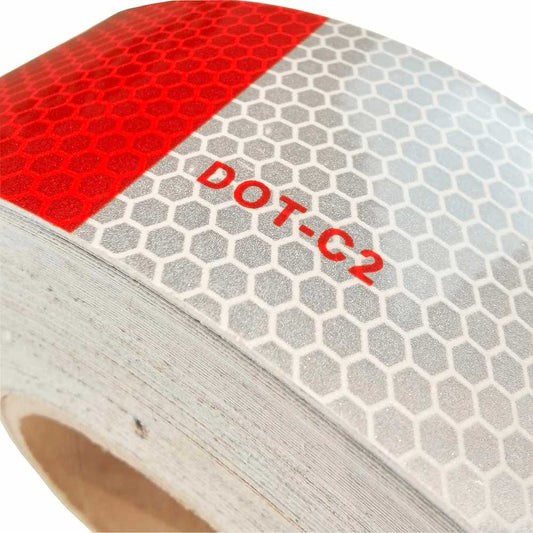

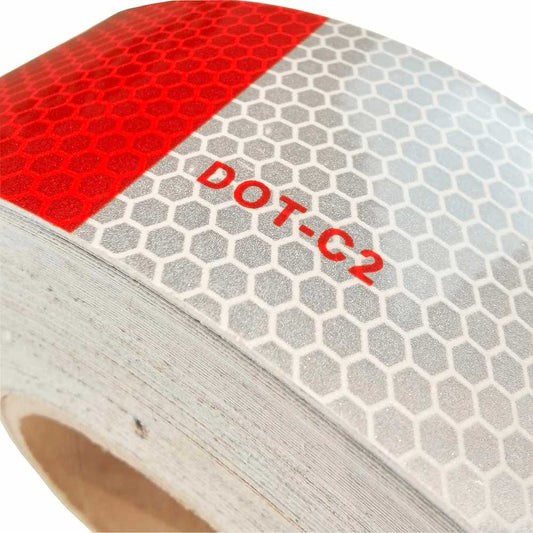

SaleDOT REFLECTIVE TAPE

Regular price $19.90 USDRegular priceUnit price per$21.99 USDSale price $19.90 USDSale -

RED DEVIL FOAM & FILL AEROSOL FOAM SEALANT - Box of 12

Regular price $120.00 USDRegular priceUnit price per -

-

TOUCH POINT WIPES (72) - Box of 6

Regular price $60.00 USDRegular priceUnit price per -

DE-ICER SPRAY - Box of 12

Regular price $36.00 USDRegular priceUnit price per -

2"X27' CARGO STRAP AND RATCHET

Regular price $25.00 USDRegular priceUnit price per$13.44 USDSale price $25.00 USD -

SOLVENT-BASED INVERTED MARKING PAINT - Box of 12

Regular price $107.88 USDRegular priceUnit price per -

WASP & HORNET KILLER - Box of 12

Regular price $120.00 USDRegular priceUnit price per -

ORANGE SAFETY FENCE - 100 ft

Regular price $38.99 USDRegular priceUnit price per$39.87 USDSale price $38.99 USDSale

CAN'T FIND WHAT YOU'RE LOOKING FOR?

Nova Industrial Safety carries thousands of high-quality safety products. If the traditional search options aren't working for you, consider looking through our entire catalogue of collections.

BESTSELLERS

-

CHIP BRUSHES - Pack

Regular price From $28.00 USDRegular priceUnit price per$9.29 USDSale price From $28.00 USD -

3 PIECE TRIANGLE REFLECTOR KIT

Regular price $29.90 USDRegular priceUnit price per -

2"X27' CARGO STRAP AND RATCHET

Regular price $25.00 USDRegular priceUnit price per$13.44 USDSale price $25.00 USD -

-

12/3 EXTENSION CORDS WITH LIGHTED END

Regular price From $99.99 USDRegular priceUnit price per -

SCRUBS IN A BUCKET - Pack of 6

Regular price $120.00 USDRegular priceUnit price per